Adopting modern technologies such as automation, robotics, and advanced manufacturing techniques can streamline operations, improve efficiency, and reduce labor costs. For instance, automated assembly lines can increase production speed and accuracy while minimizing labor-intensive tasks, thereby lowering overall manufacturing expenses. Direct labor refers to the wages, benefits, and payroll taxes paid to employees directly involved in the manufacturing process.

Importance of Understanding Manufacturing Costs

- By identifying and understanding these factors, companies can make informed decisions to manage and reduce costs effectively.

- As you produce more, your machinery’s wear and tear intensify, requiring increased maintenance and potentially additional repairs.

- This can include things like rent or other indirect materials that aren’t used to create the final product, like water or cleaning supplies.

- When scaling production, the cost of raw materials can exhibit a promising trend.

- Buying in bulk often reduces costs, as you can negotiate favorable prices and achieve significant savings.

- While allocating manufacturing overhead costs may seem daunting, there are strategies to help streamline the process and ensure accurate cost allocation.

Most manufacturers strive toward minimizing the ending WIP as it frees up capital, deflates the tax burden, and crucially, makes accounting much easier. Manually finding the precise WIP value is also complicated because overhead margins, taxes, etc., need to be calculated per unfinished work orders. In practice, most modern manufacturers use MRP software with perpetual inventory systems that calculate WIP automatically and continuously. Factory manufacturing cost provides insights into the specific expenses related to production, excluding other costs such as selling and administrative expenses. By embracing the insights gained from our exploration and implementing effective cost-management strategies, you can position your manufacturing business for long-term success. Scaling production requires careful evaluation, as not all production costs scale simultaneously.

How to calculate direct material costs

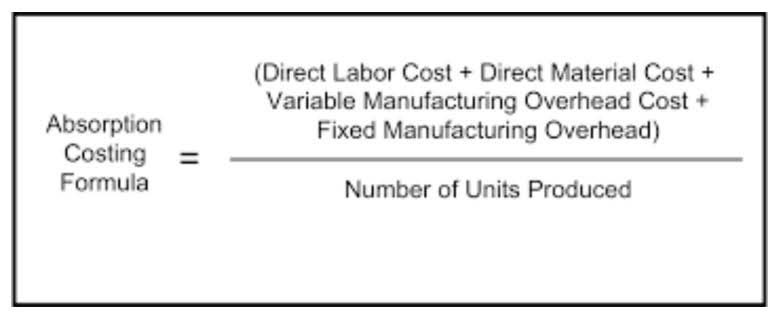

For example, in car manufacturing, steel, tires, and glass are direct materials. To calculate total manufacturing costs, https://www.bookstime.com/ you must first sum up all the direct materials used in production. Total manufacturing cost is the sum of direct materials, direct labor, and manufacturing overhead. To calculate total manufacturing costs, use the total manufacturing cost formula. Factory manufacturing costs are the total costs incurred within the factory or production facility to produce goods. It consists of costs of the manufacturing process, including direct materials, direct labor, and manufacturing overhead costs.

Manufacturing Overhead

This simple formula shows how to find total manufacturing costs accurately and helps businesses understand their production expenses. By using this method, you can easily calculate total manufacturing costs for any production process. Finally, multiply the total number of direct labor hours by the labor rate per hour. This will give you the total direct labor cost for producing the product.

- In this article we look at the details of what makes up total manufacturing costs, how to work out its component parts – and, importantly, how to reduce some of these costs in a manufacturing business.

- Indirect materials costs are also part of manufacturing overhead, such as the purchase of lubricants, grease and water that aren’t used as raw materials.

- In coffee manufacturing, for example, the cost of coffee beans is a direct material cost.

- Content of the memo must include the name and title of the person interviewed, name of the company, date of the interview, and information responding to the questions above.

- Total manufacturing cost refers to the total expenses involved in producing goods.

- Let’s calculate the 2019 total manufacturing costs for Rose Burn, which opened in 2019 and makes and sells rose candles (no relation to actress Rose Byrne).

- Prioritize precise calculations to keep your business financially healthy and optimized.

To Ensure One Vote Per Person, Please Include the Following Info

COGM also allows management to identify cash drains, adjust prices, and track the development of the business. Consider an example of calculating manufacturing costs for Flying Pigs Corporation and the company’s costs to make roller skates. While allocating overhead costs may present challenges, it is possible to overcome them and maximize https://x.com/BooksTimeInc profitability with the right approach. By adopting meticulous record-keeping practices, conducting detailed analyses, and harnessing the power of technology, you can ensure the accurate allocation of overhead costs.

Work in process inventory

Direct labor costs are those costs related to the workers who are physically involved in producing the finished product. These workers are responsible for converting the raw materials total manufacturing cost formula managerial accounting into the finished goods. ProjectManager is award-winning project management software that tracks manufacturing costs in real time. Use our kanban board as a tool to track cost estimates versus actual costs, order management and inventory management alongside production. It centralizes production processes to help you build plans and collaborate with your team. Product or manufacturing cost is the total cost incurred in producing goods.

Which of these is most important for your financial advisor to have?

Total manufacturing cost refers to the total expenses involved in producing goods. This includes direct materials, direct labor, and manufacturing overhead. Accurately calculating total manufacturing costs is essential for determining product pricing, managing resources, and maximizing profitability. By using the total manufacturing cost formula, companies can make informed decisions about cost-cutting strategies and pricing models. Knowing how to find total manufacturing costs allows businesses to compete better in the market and optimize their production processes. Manufacturing overhead is any costs related to the manufacturing of a product that isn’t direct materials costs or labor costs.

How to calculate direct labour costs

Knowing the cost of manufacturing a product is more than being able to calculate the price and profits of the item. It helps manufacturers make more insightful decisions in terms of staying competitive and how production manufacturing can be profitable enough money to remain a viable business. Flying Pigs paid its workers $38,300 in labor to make the skates, and its total manufacturing overhead expense was $17,500. By closely tracking these variations, we can make well-informed decisions, identify areas for improvement, and optimize our overall financial performance.

Leave a Reply